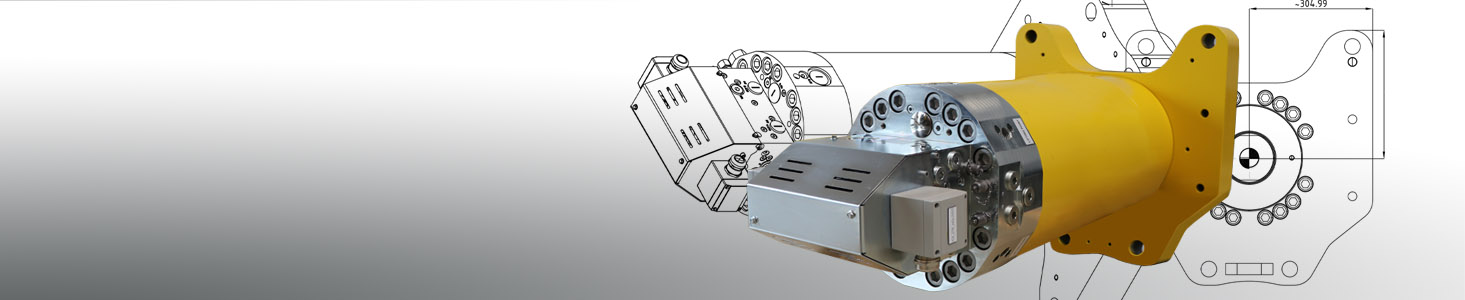

Hydraulic cylinders for the highest demands

Facts and figures

Operating area : 6700 m2

Of which: production halls 2500 m2, assembly hall 1300 m2, office 600 m2, raw material warehouse including sandblasting facility 2500 m2

Sales markets: We mainly supply original equipment customers (OEM) in Germany and Austria.

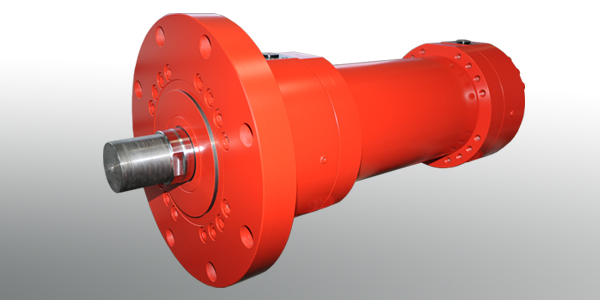

Our hydraulic cylinders are used successfully in construction machinery, steel mills, power plants and other industrial applications on all continents

Basis of cooperation

We do not see ourselves as contract manufacturer, but are your development partner for a customized cylinder solution, that offers you a real competitive advantage. From the first meeting, we work on implementing an appropriate solution for your needs. Transparency in the quotation structure, commitment from the provision of the first design drawings and careful handling of the data which you have entrusted to us ensure a trustworthy cooperation.

Project handling

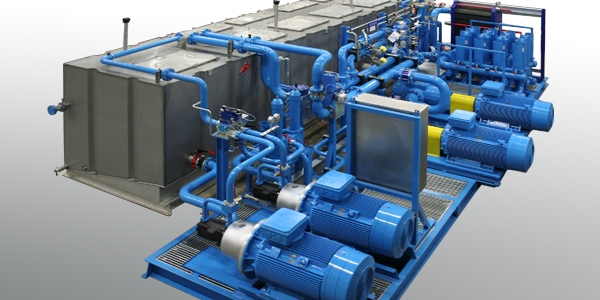

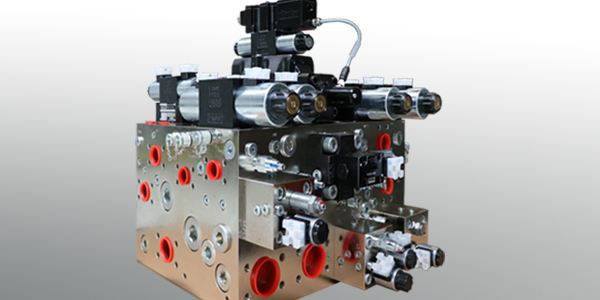

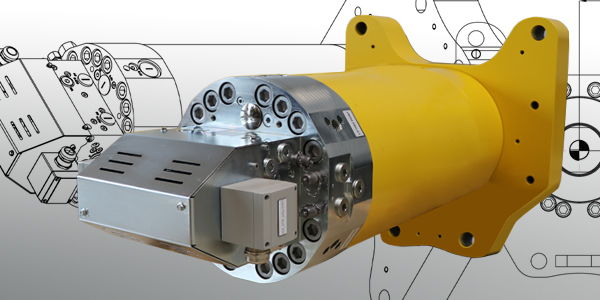

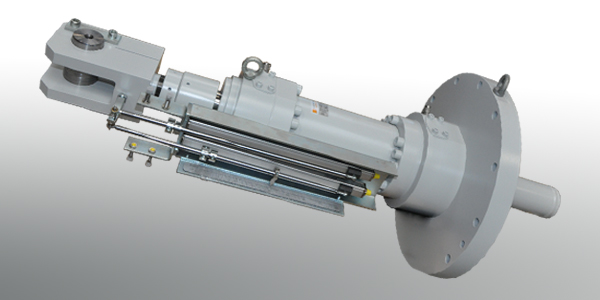

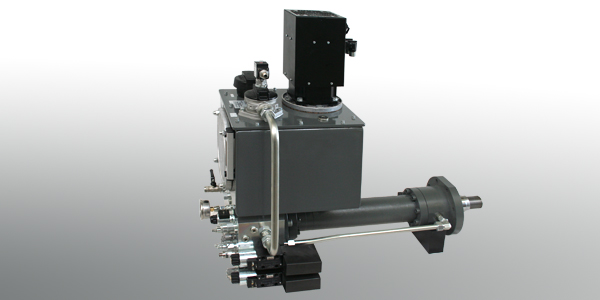

The starting point for all projects is to check to what extent the requirements can be met with a standard cylinder. Planning a custom cylinder solution also starts based on a standard series cylinder. In addition to mechanical elements, hydraulic, control and electrotechnical elements are also adapted. This allows us to reduce considerably your system interfaces.

The offer package includes a professional and comprehensive technical application advice as well as suggestions for the optimal design of the cylinder construction in terms of installation. Naturally, our service includes short design and delivery times, 3D assembly drawings, permanent ISO-certified monitoring of product and process quality, and FEM – Finite Element Modelling for critical parts.

Know-how advantage and quality standards

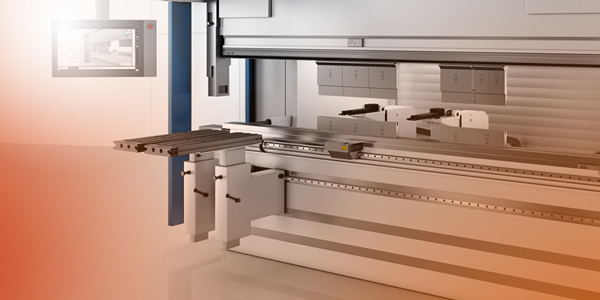

We have more than 50 years of experience in technically demanding design and manufacturing of cylinders. The heart of our production are state-of-the-art CNC processing machines and CNC lathes. On top, we work with three complete processing machines up to a component length of 3000 mm, equipped with universal milling spindle, chuck and counter-chuck for automatic workpiece transfer, steady rests as well as automated tool change from a storage with 100 tools. Our own grinding, honing and polishing machines complete the high level of vertical integration and guarantee the highest quality standards in production.

ISO-certified cylinder manufacture

Our comprehensive machine tool complex in a manufacturing area of 2500 m2 is specially suited to the manufacturing of standard, industry-related and customer cylinders for industrial applications up to 10000 mm stroke and 1500 mm piston diameter. This allows us to guarantee rapid order processing even for large projects.

Depending on the number and size, piston rods are machined on cycle-controlled lathes or CNC lathes and ground if necessary. Even long and large cylinder tubes are turned in the house completely outside and inside – with boring bar and anti-vibration holder – and honed to the finest surface roughness.

Cut-to-lengh parts or stroke-independent parts, such as heads, plates, ball joints, guide bushes and pistons, are manufactured on state-of-the-art turn-mill centers with complete machining. Boring mills and CNC machining centers in combination with classic CNC lathes prove themselves for large crosspieces. The quality assurance of the production parts is handled directly by the machine operator. For serial parts, the actual dimensions for serial number tracking are logged. Plasma cutting, automated sawing and welding systems round off the machine spectrum on the blank side. All parts are deburred, meticulously cleaned and preserved.

Cylinder assembly