Broad porfolio of drive safety technology for training tracks

Professional equipment for training centres

With innovative technology, driver training courses can be carried out in an incredibly realistic and practical manner. As the market leader, we equip driving technology centers, test tracks, drive experience centers, as well as driving schools and driver training tracks around the world.

You too can benefit from our permanently optimized products, our extensive experience, a professional range of services and introductory training for your instructors.

For our product range and technical details see our folder

Technological masterpiece – Kick plate CAR SP

With the kick plate CAR SP the dislocation of the vehicle rear is simulated. The driver can train safely the dangerous situation of a skidding vehicle in a riskless environment.

Function

The vehicle is accelerated to a speed from 25 and 65 km/hour (15 to 40 miles/hour). Approaching the hydraulic plate contact pads are crossed. The kick operation is timed exactly to the millisecond, calculated from the exact determined vehicle speed and axle distance. During the use of the kick plate it dislocates 70 cm, so that the rear swerves and the vehicle skids.

As to the level of driving skills the CAR SP can be set to a kick intensity from 0 to 100 percent. This provides ideal training-conditions for beginners as well for pros.

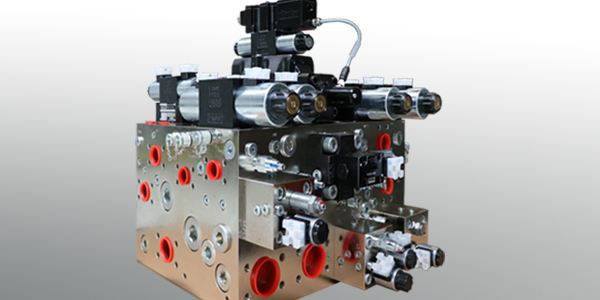

Benefits CAR SP

The hydraulic plate CAR SP from Dorninger Hytronics is technically mature and convinces with first class quality components and with reliable service.

innovative, reliable complete–solution

concise and failure–free

simple, comfortable to operate

integrated security logics

permanent winter activity possible

flooding secure construction

long durability, despite heavy operational demands

high–quality components of Parker and B&R

remote maintainance module via Internet

Further information can be found in our flyer

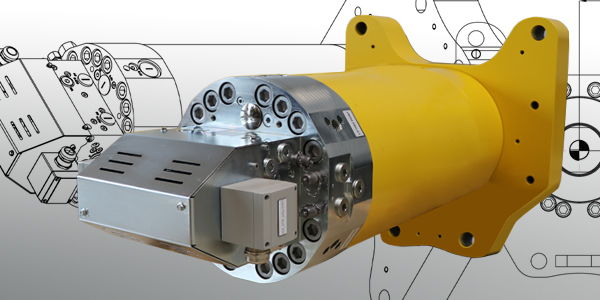

Power pack – Kick plate TRUCK SP

The kick plate TRUCK SP can be used to train the driver reaction when the rear of a lorry or passenger car dislocates and the vehicle swerves.

The hydraulic plate TRUCK SP contains a unique integrated axial counter. This counter determines the axis on which the operation is executed. This makes it possible to train different dangerous situations also with trailers. The driver can train appropriate reactions with a skidding vehicle.

Function

The truck reaches a speed between 20 and 45 km/hour (13 to 28 miles/hour), the passenger car is accelerated to a speed from 25 to 65 km/hour (15 to 40 miles/hour). Approaching the kick plate contact pads are crossed. The integrated axial counter identifies the axis on which the operation is executed. The kick operation is timed exactly to the millisecond, calculated from the exact determined vehicle speed and axle distance. During the use of the plate it dislocates 100 cm, so that the rear swerves and the vehicle skids.

As to the level of driving skills the hydraulic plate TRUCK SP can be set to a kick intensity from 0 and 100 percent.

Benefits TRUCK SP

The hydraulic plate TRUCK SP from Dorninger Hytronics is technically mature and convinces with high-quality components and with reliable service..

for use with trucks and passenger cars

integrated axial counter

exactly directed skidding on predefined axis

innovative, reliable complete–solution

concise and failure–free

simple, comfortably to operate

integrated security logics

permanent winter activity possible

flooding secure construction

long durability, despite heavy operational demands

high–quality components of Parker and B&R

remote maintainance module via Internet

New technical highlight – Kick plate BIKE SP

With the profound know-how in the design engineering and worldwide implementation of passenger car and truck kick plates, the Drive Solutions technicians have gone about the engineering of a motorcycle skid plate. The safeness of the motorcyclist was always in mind of the engineers during the development process and special precautions are taken to meet this requirement. Thanks to years of experience in driving safety technology, it was possible to establish this new technical showpiece for driving safety courses.

Function

Trainings with the BIKE SP are possible in a speed range between 25 and 65 km/h. Very important is the instructors valuation of the individual driver skill, and the therefore chosen kick intensity of the BIKE SP. Good command of the own motorcycle and a certain driving experience are prerequisite for this training. Crossing the moving plate in the ground, the driver can train how to react in dangerous situations.

Benefits der BIKE SP

Dorninger Hytronics Kick plate BIKE SP impresses with sophisticated technology, quality components and reliable service.

innovative, reliable complete solution

comfortable to operate

integrated security logics

permanent winter activity possible

flooding secure construction

long durability despite heavy operational demands

high-quality components of Parker und B&R

maintainance module via Internet

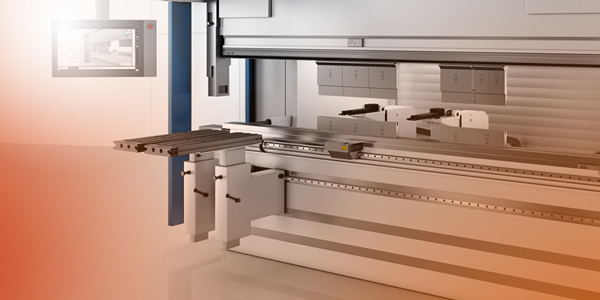

Patented development! Mechanical Obstacle MH

The sudden appearing of an obstacle on the road or at the roadside is simulated with the opening of MHs swing-flanks. The driver of a passenger car, a lorry or a two-wheeler is confronted with an unexpected obstruction of traffic and is learning that way how to react correctly and to adjust the speed according to the roads condition.

Function

The vehicle drives with an optional velocity on the proving ground. Thereby induction loops in the ground are crossed. Through this contact the Mechanical Obstacle MH opens its flanks computer controlled. The distance from the obstacle to the vehicle is always the same independently to the speed.

Now the driver has to react and to drive round the obstacle or to do an emergency brake to stop the vehicle in front of the obstacle. If the driver cannot stop in time or the change-manoeuvre fails, the swing-flanks automatically sway back into the road surface to avoid damages on the vehicle and on the Mechanical Obstacle.

Your benefits in short

The patented development of Dorninger Hytronics is simply convincing:

braking and lane-changing trainings for motorcycles, cars or trucks

simulation of realistic dangerous situations, virtual crash sound via radio possible

easy handling for trainers via control panel or tablet

easy retrofit on any track, little space required

maintainance-friendly module

reliable operation in winter

unbeatable energy efficency: up to 98 percent energy savings in comparison to water hazards

optional: Drive Vision (speed and leap time measurement) as an additional motivation for driver trainings

Popstacle – best attention to avoid anything happens

Low obstacles are particularly dangerous in traffic. Small animals and objects lying on the road are often difficult to see and a particular challenge for the driver. The only half meter high Popstacle is designed to simulate specially this risky situations.

Surprise effect

At the beginning of the training session the obstacle is not visible for the driver. An essential part of trainings with the Popstacle is the surprise effect, when the obstacle suddenly appears. Additionally the popstacle immitates through a wave movement of the single obstacles the way of an animal running across the street. This is an additional challenge for the car driver.

Your benefits in short

innovative, pneumatic, reliable function

simulation of a small compact obstacle

simple automatic handling

permanent winter activity possible

resistent against rust and corrosion

low space required

easy retrofit on each training center

Further information can be found in our flyer

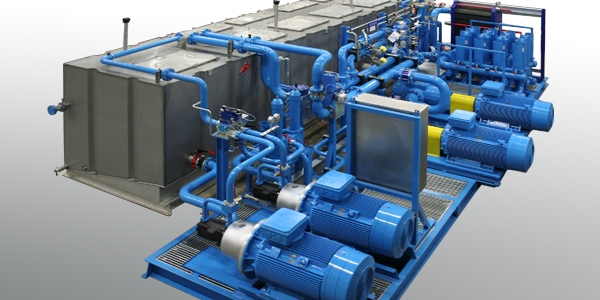

Absolutely essential - precisely controlled irrigation

Water obstacles and a precise road irrigation are indispensable in modern drive training centres. With our partners in hydrotechnology we meet all requirements for accurate placement and control of water obstacles, sprinkler and optimal design of pump stations.

Variety of training possibilities

The water obstacles or water curtains are between 2 and 12 meters long and are embedded in the road surface. The variable nozzles can be controlled and operated individually in their height so that any type of moving figure can be created. Gushing flutes and various sprinkler nozzles are available for test track irrigation. With this equipment any irrigation application is possible

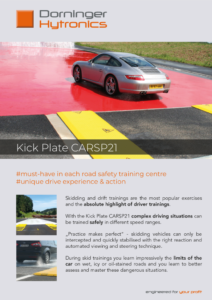

Drive Vision DV – this is pure motivation on the test track

The Drive Vision DV is the ideal addition to the Mechanical Obstacle MH. The LED display, which is clearly visible from a distance of up to 200 metres, indicates the speed exactly at the time when the driver enters in the driver training track and the speed at the simulated impact.

The luminosity of the display automatically adjusts to different lighting conditions and so is ideally visible at any time and even at a large viewing angle. Depending on the operational area we offer one-line or two-line models.

There are exciting areas of application without MH as well. A speed and lap time measurement down to miliseconds is possible for competitions.

Drive Cube DC – top designed MH control