Error-free signals guarantee stable processes

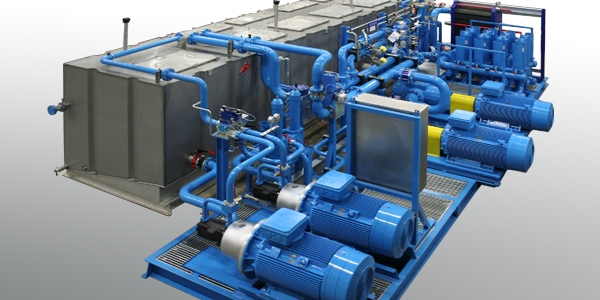

Three-phase control centres in tailor-made design

Our power cabinets are calculated and dimensioned individually for each customer and application-related. We pay particular attention to cost and energy optimization. When designing the air conditioning the control cabinet, our specialists take into account the environmental conditions prevailing on site.

We have all performance ranges from simple direct controls to star-delta drives to the use of soft starters and frequency converters in our portfolio. Wherever possible, we rely on speed control and energy-saving servo drive technology.

Areas of application are, for example, series of power cabinets for press drives or precise test bench drives.

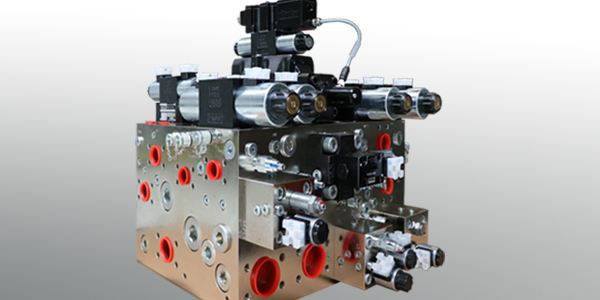

Automation of processes and systems

In addition to simple contactor and relay controls for control cabinets, our electrical professionals also design and build flexible PLC-based controls. The associated software is programmed in close cooperation with our customers. The safety for the machine operator is given by a corresponding emergency stop concept.

Our range of services includes

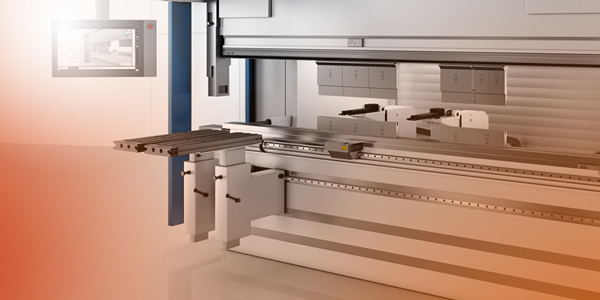

Control cabinets directly on the systems with an on-site user interface

Control cabinets for the control centre with on-site machine connection

Machine data preparation and communication systems (e.g. bus system or remote maintenance access)

Intuitive on-site controls on machines and systems