Focus on individual cylinder solutions

Focus on 100% functionally tested quality

Quality first. That is our top priority. We have a unique, fully automated function test with the cylinder test bench developed in-house which every cylinder must pass through in a large number of test steps. The desired test pressure is measured continuously over time during the leak test. By specifying tolerance windows, the permissible pressure drop can be defined on the rod and piston side and any leaks can be detected. An automated and high-precision stroke measurement is integrated. The travel pressure is recorded over the stroke during the ease of movement test. In this way, sluggishness due to assembly or manufacturing errors can be finally identified and eliminated. All data is logged and exported to the order processing system via an interface in which the test documents required for customer documentation are created. This means that the quality status at the time of delivery is clearly and provably documented for the customer.

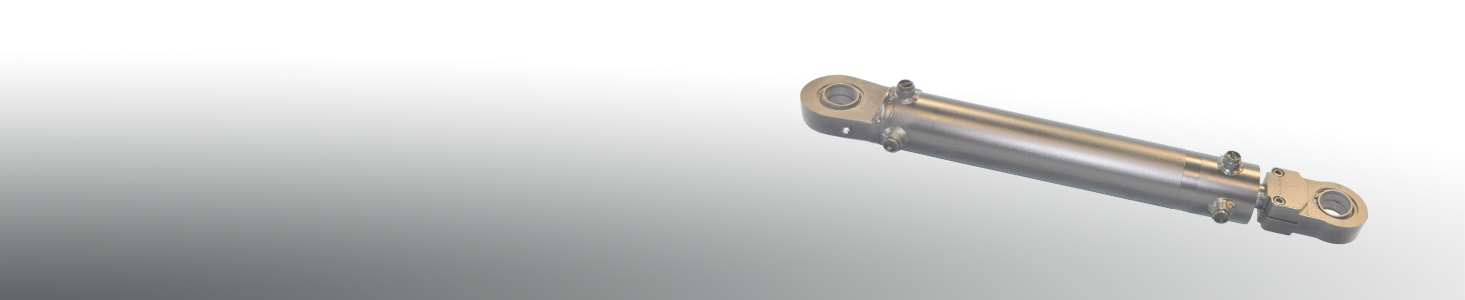

Standard cylinders - basis of success

We are specialists in individual cylinder solutions. This is based on a common parts concept for pistons, heads and bottoms which is derived from the various ISO standard series.

The parts not specifically related to stroke length are very standard components, which are batch manufactured and kept in stock. This allows us to offer you a wide spectrum of standard cylinders with very short leadtimes.

Depending on requirements, various sealing systems are available, which always present a compromise between freedom of movement and sealing function, and are to be matched to the application and operating medium. In all cases, we only use seals from well known manufacturers.

According to the type code, you can choose from our modular system, in terms of the different attachment types, position and thread of the hydraulic connections, end position damping, attachment of position sensors, and piston rod style.

Step by step to the highest power

Naturally, for cost reasons, we would recommend using a standard cylinder in the case of an easy and straightforward installation. In many cases though, often due to the requirement to integrate into existing equipment or for control system integration, it will be necessary to create a customer-specific cylinder derived from the standard cylinder.

Here, we proceed step by step using an exact milestone concept. A careful computer-assisted common parts concept, e.g. the same assembly clearances for seals, allows the process to remain cost-efficient, yet meet your requirements.

Welded hydraulic cylinders

You have the choice of the following factory standard series from our standard range up to 6000 mm stroke and 250 mm piston diameter:

Single-acting hydraulic cylinder CE 16 (160 bar)

Double-acting hydraulic cylinder CD 16 (160 bar)

Double-acting hydrocylinder CD 16 – SO 250 (250 bar)

Threaded hydraulic cylinders

You can choose up to 6000 mm stroke and piston diameter of 250 mSpem from our standard range in the following series:

Double-acting hydraulic cylinder CD 16 P to ISO 6020/2, tension rod version (160 bar)

Double-acting hydraulic cylinder CDS 1 to ISO 6020/1 (160 bar)

Double-acting hydraulic cylinder CDV 1 to ISO 3320 (250 bar)

Double-acting hydraulic cylinder CDV 2 to ISO 6022 (250 bar)

Double-acting hydraulic cylinder CDV 3 to ISO 3320 (350 bar)

For technical details, please contact our sales team on telephone +43 7236 20820 0.

Always focused on the customer application

From the first discussion, we work on implementing an appropriate solution for your needs. Transparency in the quotation structure, commitment from the provision of the first design drawings and careful handling of the data which you have entrusted to us ensure a trustworthy cooperation.

Our cylinder solutions fulfil your requirements

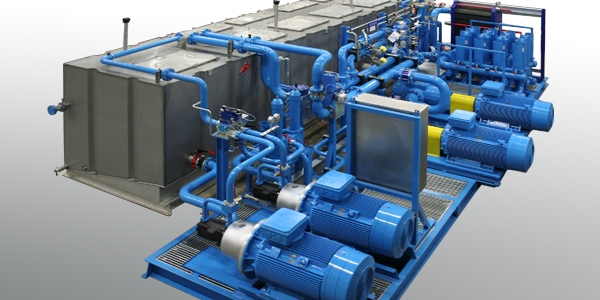

Our engineering competence extends to a wide range of sectors: metallurgy – rolling mills, continuous casting plants, furnaces; energy technology – water, gas, wind; pressing machinery – plastics technology and metal pressing; special and construction machinery and many others. No matter which sector you are in, we focus on your business, your requirements and your specifications.

Short installation lengths, special low-friction applications, additional mechanical assemblies such as locking devices, water-cooled hydraulic cylinders, special steels for piston rods and cylinder tubes, manufacture from solid material for particularly extreme conditions, piston rod locking, addition and integration of control blocks and position sensors – we provide the solution.

Precision, speed, reliability, robustness, long life time and low-maintenance technology – it is our duty and obligation to meet the varying demands and applications of your sector.

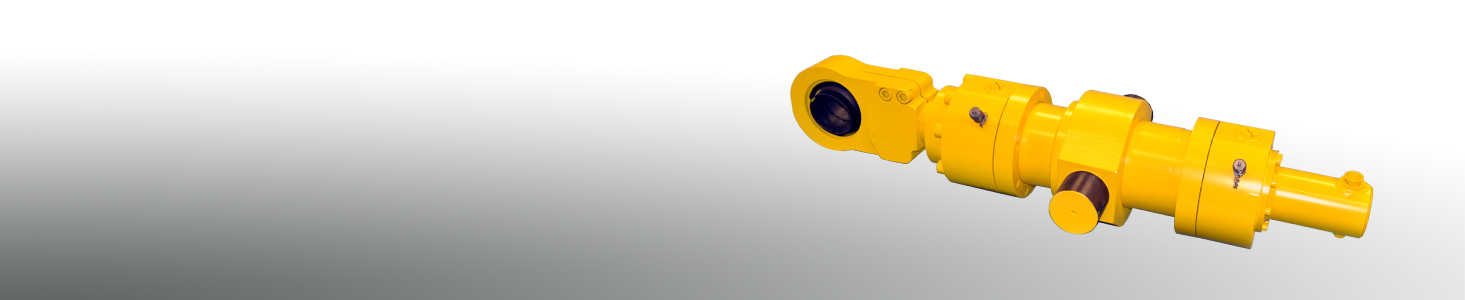

Hydraulic cylinders for the metallurgy

Hydraulic cylinders for the metallurgy are exposed to especially demanding conditions. With our diverse machine park from CNC machining centres to complete machining turning centres and our manufacturing expertise, we can optimally manufacture the wide range of hydraulic cylinders for rolling mills, continuous casting plants and furnaces.

Special cylinder housings made of solid material are manufactured on our CNC turning centres with the highest cutting performance and honed with precision on our in-house honing machines.

Our unique manufacturing specialities are special piston rods with bores for position measuring systems up to 6 meters in length or thick-walled cylinder tubes with internal, axial control lines and radial connection surfaces and threads. These are processed completely at once on our TC machines with chuck and counter-chuck without any intermediate steps. In terms of production technology, nothing is too heavy for us up to a component weight of 8 tons.

Quality features for the reliability of our hydraulic cylinders in the metallurgical industries are the robust manufacture and very good resistance to external impacts. Sophisticated sealing concepts with special wipers and special surface treatment methods for the piston rods ensure this. Versions with water cooling or forged piston rods open up new possibilities for meeting the highest demands.

Cylinders for power engineering

We are a specialist for the manufacture of hydraulic cylinder for guide vane adjustment for hydro turbines and flap cylinders for hydraulic steel construction.

Our hydraulic cylinders for energy technology optimally meet the special requirements with regard to material testing and paint quality: Assured roughness and purity through sandblasting and degreasing, documentation and measurement of roughness depth, surface cleanliness, dew point, moisture, layer thickness and the control of the hardening time in a temperature-monitored drying cabin ensure the high-quality processing of demanding paint structures for the desired corrosion resistance.

In addition to the usual material certificates according to EN 10204, we can offer special materials with regard to notched impact strength and structure quality. Special tests of the tube and piston rod (MT, PT, UT), chrome layer thickness logging, weld seam tests and pressure and function tests of the finished cylinders are the basis for maximum round-the-clock reliability in long-term operation and a long service life; It is also conceivable for the parts wetted with water to be made of stainless steel of different quality and toughness.

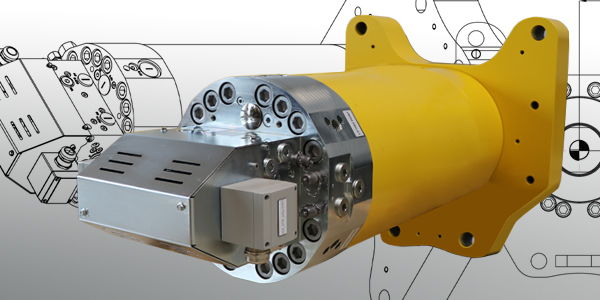

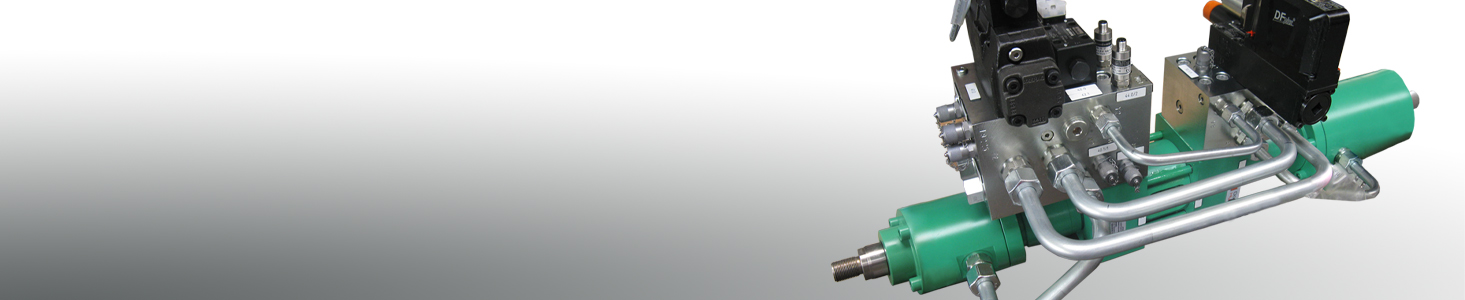

Hydraulic cylinders for automation

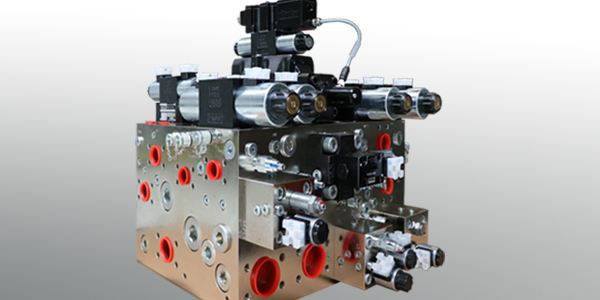

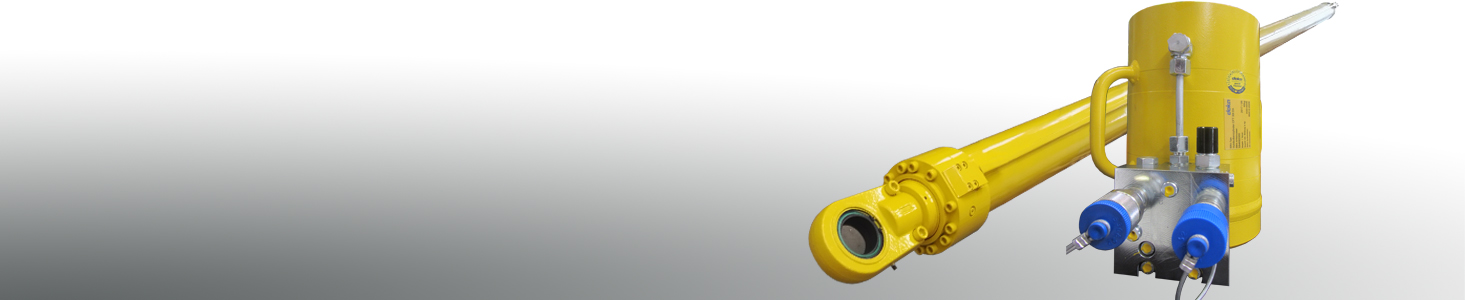

Under hydraulic cylinders for automation, we subsume the wide spectrum of electrohydraulic control axes, consisting of hydraulic cylinders, position measurement system and control block with control valve, which is often mounted directly to the hydraulic cylinder.

For many applications, this means using a customer-specific special cylinder. Example: Two double-acting hydraulic cylinders 63/45, 150mm stroke, mounted in opposing directions via a tension rod arrangement, with SSI encoder and mounted control blocks with NG6/10 control valves, first hydraulic cylinder set up as pre-positioning cylinder with piston rod clamping, second hydraulic cylinder as active position controller.

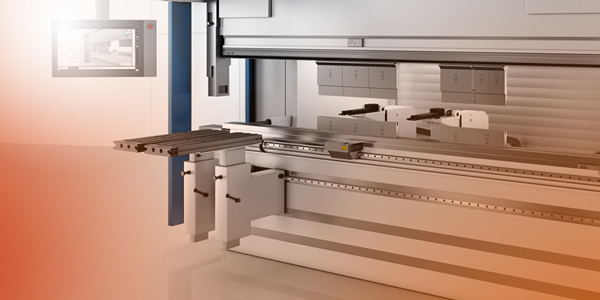

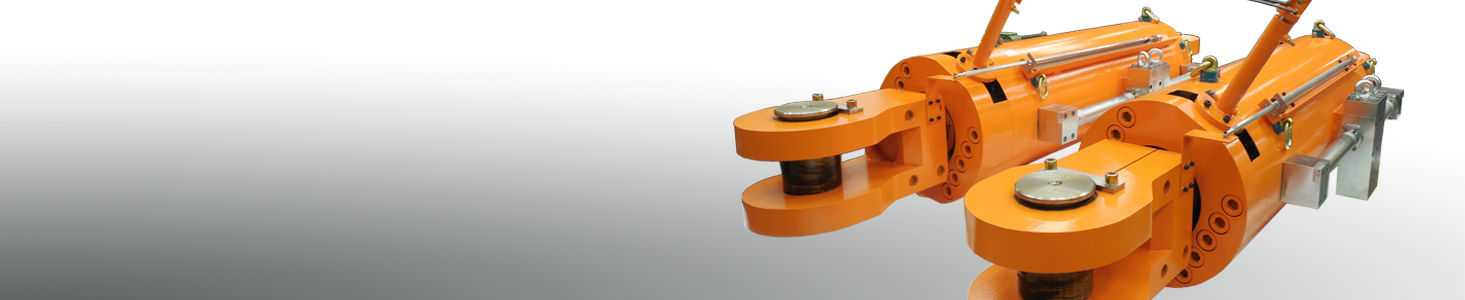

Hydraulic cylinders for pressing machinery

Our hydraulic cylinders for presses prove themselves in the most varied applications, no matter whether plastics, metal or wood press forming, no matter whether single or series cylinders for moulding.

We have the right design solution and manufacturing technology. We can assemble special press cylinders up to a total weight of 20 tons. Our TC complete machining centres are used for series cylinders for moulding. Serial number management for part tracking is a matter of course. We solve challenges such as high pressures and higher temperatures with special sealing concepts.

Our specialists design plunger cylinders and cylinder bases with integrated filling valves that are optimal for the application. Radial forces which can occur on the piston rod require a robust manufacture.

This is how we can put the technically ideal cylinder type into practice for your specific application and intended use!

Hydraulic cylinders for the construction industry

We have also made a good name for ourselves for special cylinders in the construction industry. The range of applications is diverse: extremely wear-resistant and high-frequency oscillating cylinders for ballast compaction, handling cylinders with integrated position measuring systems or long-stroke cylinders for formwork technology.

The steadily growing cities of this world also require innovations in construction processes. We are on board with a long-stroke cylinder specially developed for formwork technology. The picture shows a cylinder with a stroke of over 7,000 mm and a control unit integrated into the cylinder base.

On the largest construction sites in the world, hydraulic cylinders manufactured by us lift the platform, formwork, material container and concrete distributor into the next concreting section in just one stroke without a crane.

Economic self-sufficiency