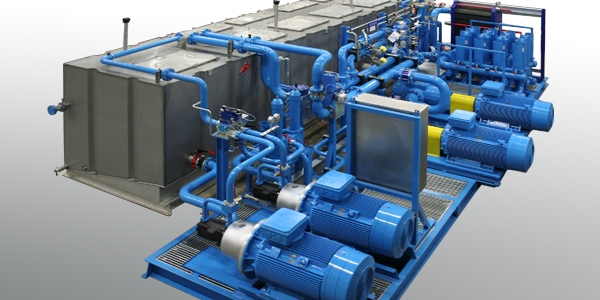

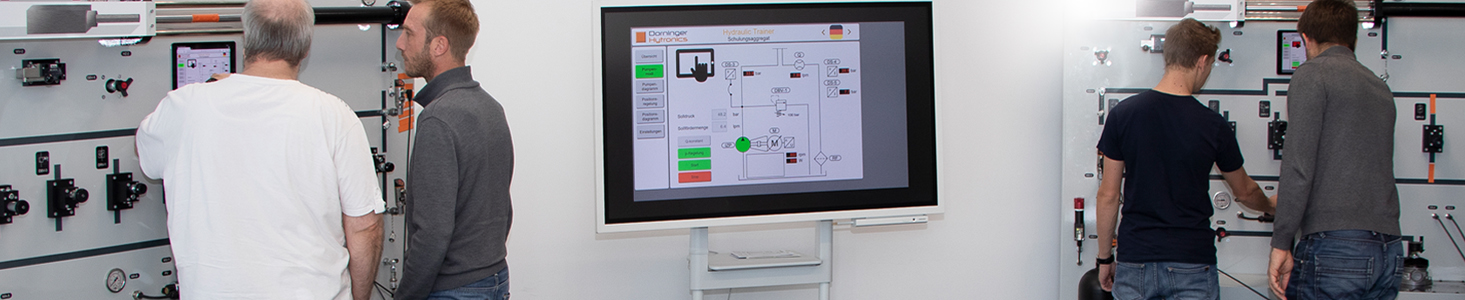

Our range of products extends from compact units to units with a 40,000 litre tank volume and 250 kW. Special units with electric control cabinets, servo pump drives and explosion protection as well as pump sets complete the portfolio. Convenient training units for basic and advanced training are also available.

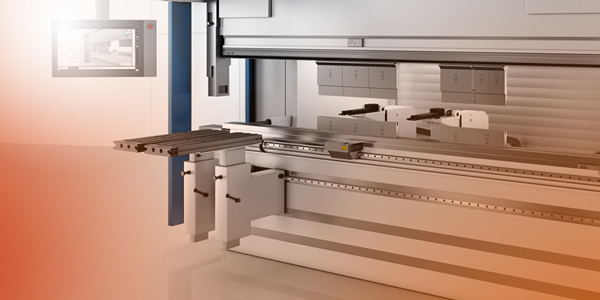

Our sales and engineering professionals work with you on the perfect design and implementation. You will receive imaging “as built” 3D drawings, precise documentation including all manuals, test reports, assembly drawings and technical data sheets. On-site commissioning is carried out on schedule, including extensive training for the operating personnel. Even after your system has been delivered, our specialists ensure long-term customer support.

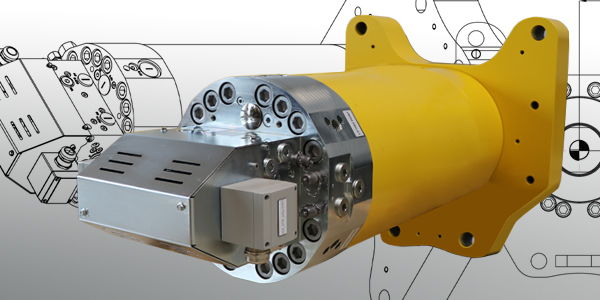

Regardless of the industry, we adapt to your needs and specifications, whether metallurgy, paper industry, plastics technology, special machine construction or energy technology – no matter which sector you operate in – we use our expert know-how to meet your demands and applications.

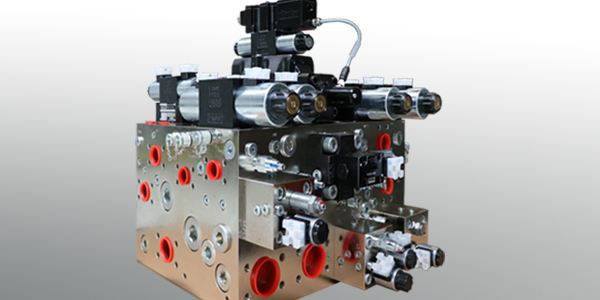

If you are looking for a competent, reliable and experienced supplier with your complex mechatronic requirements, then we are the ideal engineering and outsourcing partner.

We guarantee

Precision and a maximum of efficiency and productivity

Greatest possible security

Robustness and therefore a long service life

Maintenance-friendly technology.