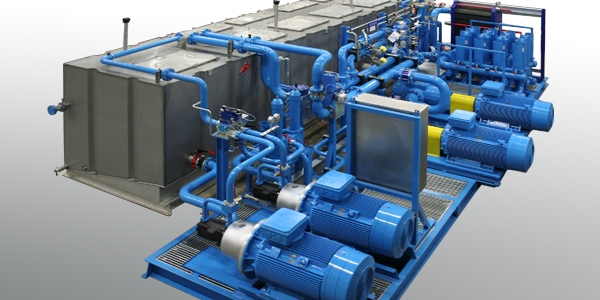

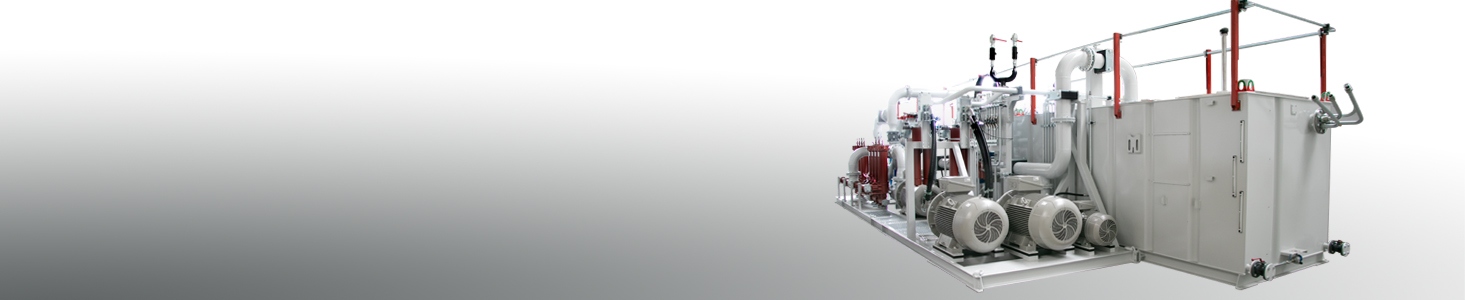

Tank and pump stations - the premier class

We can implement structurally optimized tank stations for you with a tank volume of up to 40,000 litres and pump stations with a drive power of up to 200 kW per pump set.

Thanks to our many years of experience, we know how tanks must be designed for different media and which materials are to be used. Stabilizing plates and the corresponding design of the tank chambers prevent foam formation and ensure the optimum flow of oil through the tank. Simple filling and emptying of the tank guarantee a high level of user-friendliness. With a view to the oil volume requirement of the overall system, the tank volume is designed to be as small as possible so that environmental and cost aspects are equally taken into account.

The high-pressure pump sets up to 300 bar and 350 ccm are optimized in terms of piping and connected to the filling station to save space.

The top priority for us is the tightness of the tank and piping as well as the high-quality and visually perfect execution of the steel construction. For this purpose, we have built up a long-term supply chain with a stable exchange of information with several Eastern European steel construction manufacturers. The quality standards are specified by us and the suppliers are regularly audited for compliance. So there is no contradiction between low manufacturing costs and high quality.

We are certified as a welding company in accordance with ÖNORM EN ISO 3834-2 and can thus ensure that our welding staff make the weld seams in accordance with the relevant standards.

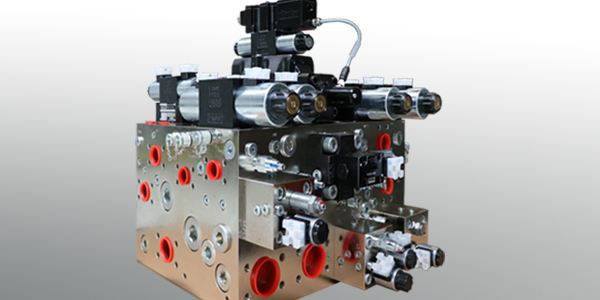

Valve stands – control units squared

You have also come to the right place with valve stands. Here we combine our expertise in the design and manufacture of control units with our knowledge of piping and steel construction, beneficially for you. We apply the following design principle “As much unit as possible, as little piping as necessary”. In this way we can avoid potential sources of leakage and keep the overall design comparatively small and clear.

We take care of the switching logic of the hydraulic valves, construct the optimal control unit, select the appropriate valve components and sensors regardless of the manufacturer, and pipe the whole thing into a clear assembly.

Of course you have the last word. After the suggestions of our project management, you give the final approval of the valve assembly. In close cooperation with you, the functionally and structurally perfectly coordinated valve stand is created for you.

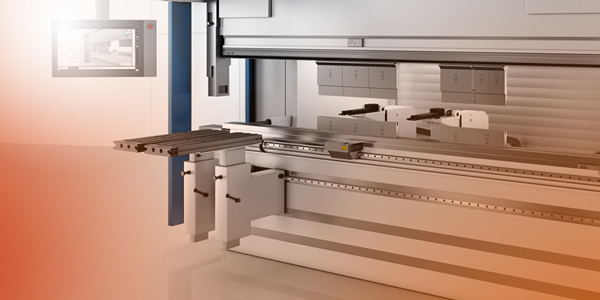

Valve tables – fit for use

For maximum convenience and benefit, you can obtain your valve table from us completely piped, wired, ready for connection and turnkey with remote IO boxes. In the sense of plug and play, all interfaces are cleaned up and brought together in a clear arrangement for you. All hydraulic and electrical parameters are preset by us. This is easy to use and maintain.

We carry out the complete hydraulic function test using software for valve tables with remote IO. This eliminates the need for costly “programming work” for the customer when commissioning on the construction site. A three-fold benefit for you: cheaper, more accurate and faster!

We support you with the design, especially for applications in metallurgic industry and in harsh environmental conditions. The right surface protection in an aggressive environment, the right devices and seals depending on the viscosity and medium, the right piping system and much more. Consult our experts!

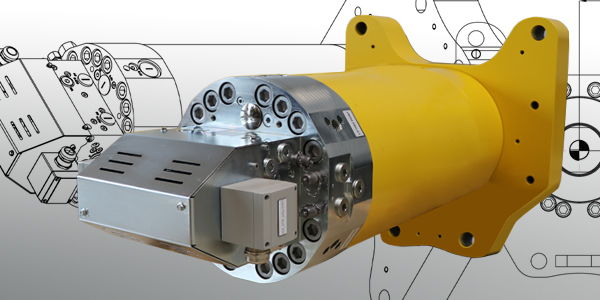

Valve boxes – protected technology

Complete covering is a tried and tested means of protecting valve technology from water, dust or salt.

We have a variety of shapes for this – the valve box, the valve chest, the valve cabinet or the covering of a valve table. The full hydraulic and electrical technology is hidden under the protective cover. The advantage: compact, protected and ready for connection.

When designing the safety-compliant control of the valve chest, we score with the design based on the special performance level to be defined by you (PL – probability of a dangerous failure per hour). With the optimal interaction of hydraulics, electrics and PLC, you are well equipped for the future.

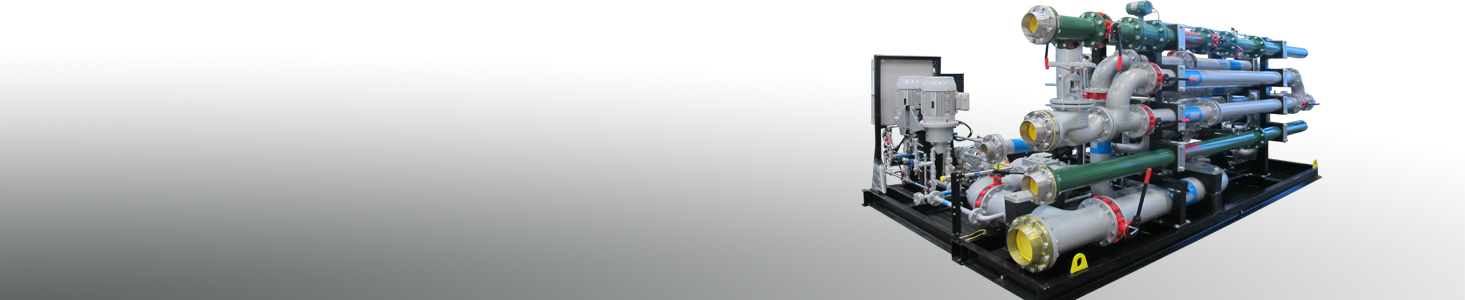

Accumulator stations – energy on demand

We dimension the accumulator bench for you in terms of size, medium, material and design. Bladder accumulators or piston accumulators are used. We also cover user-related special designs such as piston accumulators with position monitoring, with safety-relevant devices or in ATEX design.

Lubricating oil systems – from small to large

From small units for gear oil lubrication with low flow rates to integrated large systems for the lubrication, cooling and filtration of paper machines with integrated high-pressure parts – we cover a wide range of lubrication systems.

In case of complex projects, we start with an on-site meeting and sound out the requirements prescribed. The professional implementation is carried out together with you by our experienced and technically skilled sales professionals.

You benefit from our extensive knowledge in tank design to calm the medium and from our sophisticated air separation concepts. Another plus: our experience with the control of highly viscous media and with the reduction of vibrations and noise. Optimal Fluid Condition Monitoring ensures that the system has a long service life.

Container hydraulics – a future-oriented complete package