All test benches are designed in accordance with the Machinery Directive 2006/42/EG

Protection for the operating personnel through suitable protective separating devices

Protection for the test object through adjustable limit values

Protection for the test bench, even if the test object is damaged

Dorninger Hytronics production test benches are used worldwide. Defects in tested products can be recognized in the test phase, the overall defect rate drops significantly.

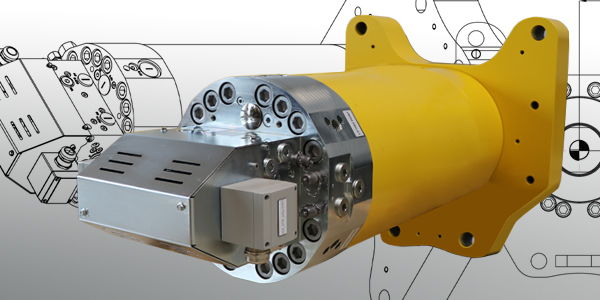

We have a know-how advantage over many other test bench manufacturers when it comes to hydraulic components. You can communicate with us from specialist to specialist in technical language, we know what your components have to perform and, thanks to our high degree of professionalism, we are able to understand your special requirements. This enables us to develop and plan the optimal test bench for your products.

The complete conception and implementation of the test benches as well as the programming of the software takes place in our development department. The engineers are all highly specialized mechatronic and perfectly familiar with the product requirements.

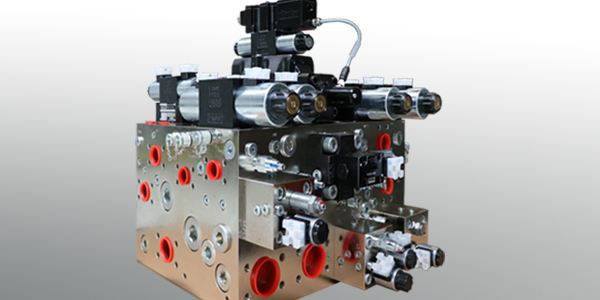

On our control block test benches, ready-configured single blocks or valve blocks based on a modular construction (e.g. valves for mobile hydraulics) can be put through comprehensive functional testing under realistic conditions. Standardised and controlled quality tests ensure reliable and repeatable test results.

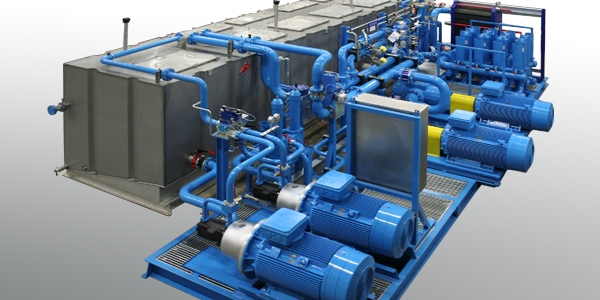

Pressure area and single test circuits are specified according to the test results and customer requirements. During the project planning phase, the tank systems will be sized, and the choice of operating types considered (hydraulic, manual, electrical).

We place particular emphasis on providing a compact and ergonomic design. For this reason the hydraulic chamber is generally accessible for maintenance, the test area includes easy-opening sliding doors to make connecting hoses and removing the test pieces easy. The programming of the soft is done in house by our highly specialised development engineers.

Functional tests of the individual components

Functional tests of the complete assembly

Recording of characteristic curves (pressure-volumetric flowrate)

Leak tests

Determination of actuation times

Standardized and controlled quality tests assure reliable and repeatable testing results

Dorninger Hytronics pump test benches for final testing of pumps are in use all around the world. There is a connection to the customer-specific ERP system for automated measurement data storage. For serial production, it is possible to capture a saved test record with a serial number for each test piece, via an automated test sequence with preset tolerance values and automated documentation. Special solutions with fully automatic pump recording and robot connection are possible..

Check across the complete specification window of pressure and volumetric flowrate

Determination of efficiency curves

Analysis of the frequency spectrum

Complete start-up phase of pumps and motors can be run on the test bench

Continuous load and fatigue tests are possible on development test benches

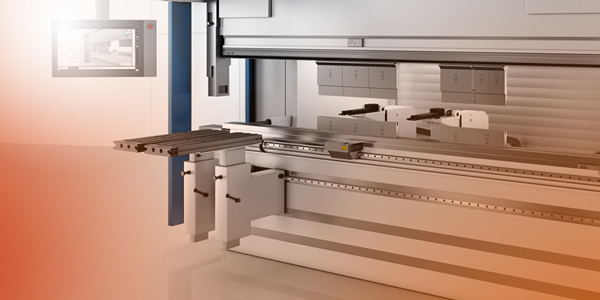

50% reduction in energy consumption during cylinder testing through a regulated servo pump concept and 50% noise reduction

Significantly shorter test cycle times thanks to energy efficiency and rapid thermal stabilization

Integration of the test bench control, recipe management and the evaluation function on a single industrial PC, i.e. no interfaces and fully automated

Simple operation by trained personnel (no skilled workers required)

Testing of series cylinders and special cylinders in a test bench

Testing of cylinders up to 700 bar and with integrated functional logic

The cylinder testing and emptying are fully automatic. The test pressure is measured continuously over time during the leak test. By specifying tolerance windows, the permissible pressure drop can be defined on the rod and piston side and any leaks can be detected. An automated and high-precision stroke measurement is integrated and there is no need for manual stroke measurement using a tape measure. The travel pressure is also recorded over the stroke during the smoothness test. In this way, sluggishness due to assembly or manufacturing errors can be finally identified and eliminated. All data is logged and exported to the order processing system via an interface in which the test values required for customer documentation are derived. This means that the quality status at the time of delivery is clearly and provably documented.

The two-part test area is also unique: on the one hand, a fully automated cabin with safety glazing for cylinders with a total length of up to 3.5 meters which is closed over the test cycle and, on the other hand, a test field for long-stroke cylinders up to 19 meters, shielded by a safety fence. Both test areas are operated from a common, energy-optimized servo test bench. Control units developed by us are used for high pressure testing and the pneumatic draining of residual oil from the cylinder.

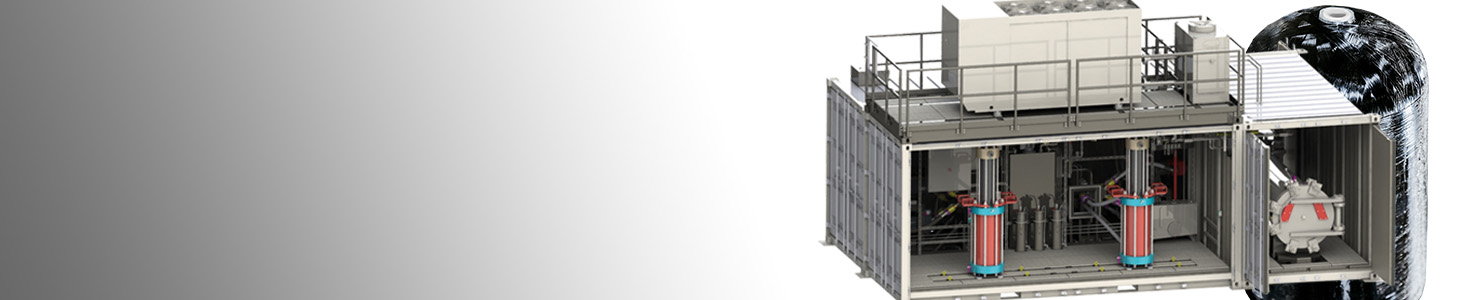

Our high-performance hydraulic pressure pulse test benches for safety testing of hydrogen tanks are unbeatably energy efficient and can be seamlessly integrated into series production. For example, TypeIV containers – high-pressure tanks made of carbon fiber composites that are filled with up to 700 bar compressed hydrogen.

A key advantage of our system is its ability to recuperate hydraulic energy back into electrical energy and so to save a massive amount of CO2. The test procedure is based on a servo pump with energy recovery and a pressure intensifier from oil to water high pressure. With our patented testing process, we achieve energy savings of up to 82 percent compared to high-pressure water pumps!

Energy savings up to 54 % and 2.8 tons of CO2 with our standard system – servo pump with energy recovery

Energy savings up to 82 % and 4.3 tons CO2 with our interlligent, patented testing method

Here you find our flyer with more information on our innovative ATPC H2-test bench:

The heart of our test bench is an oil-water double-stroke pressure

intensifier which we use for testing of transportable gas cylinders made of composite materials or carbon fiber composite materials to comply standard DIN EN 12245:2022-08 and standard DIN EN 17339:2020.

We impressively demonstrate our know-how and expertise in hydraulics, electrical engineering, and mechatronics in pressure testing of Type IV H2 tanks with1.5 times nominal pressure. (nominal pressure up to 700 bar)

From an innovative and automated test setup to detailed data acquisition and data presentation, we provide you with an unbeatable, technically perfect complete package..

You can download the information flyer about our pressure resistance test bench here:

The testing of new developments and the execution of experiments are among the possible areas of application that can be covered with our development test benches. Performance and resilience can be ensured before entering the market.

Application areas in product development

Examination of new developments, further developments, product improvements

Testing of prototypes, small series

Determination of parameters and limit values for different operating conditions, e.g. for creating data sheets or characteristic diagrams

The performance for the test is provided hydraulically via the pressure and volume flow and mechanically via speed and torque. Different loads can be generated statically and dynamically. The measurement technology is tailored according to customer requirements. The focus can be, for example, on measuring accuracy, measuring speed or data recording. All process parameters are recorded and documented. The operating status is constantly recorded in the test bench. Self-diagnosis is used to identify problems on the test bench which also includes defects in test bench components.

In addition to production companies, customers interested in development test benches also include research institutions and universities who rely on our expert knowledge and expertise.

The cyclical, dynamic loading of products can be simulated with pulse test benches. A prescribed number of test cycles with different pressure peaks is carried out.

With dynamic or static test conditions, the hydraulic components are tested under real operating conditions, e.g. to determine the product service life or the achievement of prescribed load cycles.

Suitable example, e.g. an endurance test bench for axial piston pumps with the following specifications:

Hydraulic circuits

Hybrid load Unit pmax = 550 bar, Qmax = 120 L/min

Proportional Valve pmax = 350 bar, Qmax = 200 L/min

Pressure limiting Valve pmax = 420 bar, Qmax = 120 L/min

Efficiency measurement pmax = 420 bar, Qmax = 120 L/min

Rated power of test drives

Test drive 120 kW

Load drive 120 kW

Load drive 67 kW